At Intercoastal Air we proud ourselves as a company that can install, service and repair all kind of Chillers and water source systems. Our high educated and trained technician are experts in this field are always ready to service our customers of that need. We are equipped with the right computers and hand held devises to diagnose any issue in this systems. This systems are extremely expensive to repair and or replace, call us today to schedule a preventive maintenance for your chiller system.

Here are some different water chillers and how they work:

Water Chillers

Water chillers are backbone of HVAC cooling systems. Water chiller is a refrigeration machine which produces chilled water (Approx. 7 Degree C ~ 12 Degree C).The primary function of a chiller is to lower the temperature of water to such value such that it can be used for producing cooling effect in integration with other HVAC components.

A water chiller is just like another refrigerator machine but instead of keeping your food cool or making ice, it produces chilled water. The output of chiller is a water at lower temperature usually around about 10 o C depending upon the Chiller design.

HVAC water chillers play vital role in any HVAC systems along with other basic components. Chillers have got much attention in recent years for its new designs and performance improvement in existing designs. New designs have resulted in HVAC chiller with better efficiency and less operation and maintenance costs. Another desirable features is energy saving and precise load or capacity control for new chillers. We see the chillers with above features in market but as engineering professionals we hope to see more with design improvements with less O & M cost. It is essential part of HVAC system to have a chiller.

Chiller manufacturers have also expanded their production as well design capabilities to cater to the diversified demands of HVAC chillers.

HVAC Chiller Basics

Working Principle of Vapor Compression Chiller an HVAC chiller works on vapor compression or cycle. In vapor compression cycle, refrigerant circulates in evaporator, compressor, condenser and expansion valve of a chiller. A thermodynamic process occurs in each of above chillers. Theoretical working of Vapor compression or compression chillers is explained below.

Heat addition to refrigerant in evaporator ( 1-2):

Refrigerant gets vaporized by taking heat from chilled water in evaporator thus serving its prime purpose. Refrigerant comes out of evaporator as vapors but on other side chilled water is produced. Thus heat is added to refrigerant at constant pressure but is extracted from chilled water. Both refrigerant and chilled water don’t get mixed and are separated by some solid wall in between them in evaporator like shell and tube design.

Compression of refrigerant vapors in compressor (2 – 3 ):

Refrigerant vapors come out of evaporator and then compressed by chiller compressor to high pressure and temperature. Compressor requires energy input for its working and hence electric energy is supplied to it.

Heat rejection by refrigerant in condenser ( 3 – 4 ) :

Similar to evaporator, but reverse is happening here. Refrigerant rejects its heat to outside cooling liquid or air .In this way, refrigerant gets condensed and outside media is heated. Outside media e.g. cooling water may be cooled by cooling tower and recycled again into condenser.

Expansion of refrigerant in expansion valve ( 4 -1 ) :

Refrigerant in condensed form coming out of condenser is expanded in expansion valve and its pressure and temperature is reduced to level of evaporator so that above cycle is repeated again.

In above four components of hvac chiller, evaporator is the part where we get chilled water after exchanging heat with refrigerant.

Chiller Types have been designed to cater to the diversified requirement of industrial chillers. Water have evolved due to the variety in availability of type of energy at industry or small level. Types of chillers have made the use of the chillers flexible in terms of energy input.

Industrial research in the field of chiller has eased the selection of chillers in an economical and robust manner. There is no need of worry whatever type of energy you have available with you.

Each type of chiller targets the specific users classified on the basis of type of energy they have.

HVAC systems employ different types of chillers within the available resources of clients or users.

A chiller may be the best option for particular application while the same chiller may costly or less feasible for another application or plant.

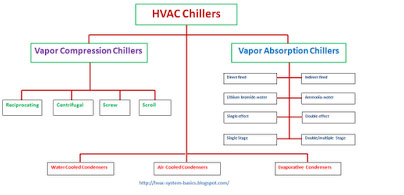

Hvac water chillers are classified primarily on the basis of cycle on which they work.

Vapor compression chillers are further classified on following basis.

While Vapor absorption chillers are further classified as following:

HVAC Absorption Chillers vs Electric Chillers

In any HVAC system, selection of chillers involve many factors to be considered judiciously. These factors simultaneously present many advantages and disadvantages to end users. For the selection of water chillers,HVAC engineers consider all these factors keeping in view all the resources they have at their facility.

Comparison of Absorption Chillers and Electric (Compression) Chillers

Following is the comparison of absorption chiller and electric chiller is presented below with aim to help you to decide the type of chillers for HVAC system.

1. Absorption chillers have COP (coefficient of performance) of only 0.54–1.1 and it competes poorly with electric chillers (rotary compressor chillers). Electric chillers on other hand have COP from 1.0 ~ 8.0.

2. Absorption HVAC chillers occupy approximately 50% more floor area than the equivalent electric chillers (vapor compression chillers).

3. Additionally due to height of absorption chillers, mechanical equipment rooms must be 6–10 ft. taller than rooms housing electric chillers. Finally, because the liquid solution is contained in long, shallow trays within an absorption chiller, the floor must be as close to absolutely level as possible.

4. In HVAC system, Absorption chiller will weigh at least twice as much the equivalent electric chiller (vapor compression chiller).

5. Due to greater size, absorption chillers are sometimes shipped in several sections, requiring field welding for final assembly. This is not case with counterpart electric chillers or compression chillers.

6. Most of electric water chillers are shipped from the factory with their refrigerant charge installed. While the refrigerant and absorbent (including additives) must be field installed in absorption HVAC chillers.

7. When we talk about noise and vibration, absorption chillers (unless direct-fired) are quiet and essentially vibration-free as compared to compression chillers (electric drive chillers). Noise and vibrations in HVAC system annoy more than anything else.

• Ventilation System

• Heat recovery ventilators

• Installation

8. Due to the potential for crystallization of the lithium bromide in the chiller if it becomes too cool, the condenser water temperature must be kept above 75–808F.There is no problem of crystallization in electric chillers (vapor compression chillers). Forget about the crystallization and stay cooled if you have installed compression chillers.

9. Absorption water chillers require sometimes an emergency power source if lengthy power outages are more often expected. Without power and heat input, the chiller begins to cool and the lithium bromide solution may crystallize. However, as absorption chillers consume very little electric energy so a small dedicated back-up generator can serve this purpose well.

10. HVAC system also gives importance to the amount of heat to be rejected in condenser by water cooling or air-cooling media. The heat rejection rate from the condenser of lithium bromide chiller is 20–50% greater than for the equivalent electric chiller, requiring higher condenser water flow rates and larger cooling towers and condenser water pumps.

11. Finally, an indirect-fired absorption water chiller will be at least 50% more expensive to purchase than the equivalent electric-drive chiller. Direct-fired absorption chillers will cost almost twice as much as an electric machine, and have the added costs associated with providing combustion air and venting (stack).

12. Absorption water chiller or lithium bromide chiller uses natural refrigerants such water and eliminate the need of CFC or HCFC refrigerants which have high global warming potential.

13. If you have plenty of waste heat or direct fire available, and want to reduce your electric load, then probably absorption chillers are the best solution. But obviously all above factors are to be considered for the selection of HVAC water chillers.

Moved into a house that needed some work last year and quickly learned the pangs of ownership had a lot to do with finding reliable, professional contractors. The furnace was on its last leg and from the very start it was issue city.

Address:

1234 SW 6th Pompano Beach FL 33069

Telephone:

305-615-COOL(2665)

954-654-7788

Fax: 768-520-4434

E-Mail - office@intercoastalair.com